Expandable polystyrene (EPS) resin manual

Expandable polystyrene (EPS) resin manual

Expandable polystyrene (EPS) resin

1. Scope

This standard specifies the product classification, requirements, test methods, inspection rules, standards and packaging of expandable polystyrene (EPS) resin. Transport and storage.

This standard is applicable to the expandable polystyrene (EPS) resin which is polymerized by the suspension method of ethylene and added with a certain amount of foaming agent, hereinafter referred to as EPS resin. Products by foaming molding, mainly used as insulation, heat insulation, shockproof packaging materials and floating products.

2. Normative references

The following documents are essential for the application of this document. For dated references, only the dated version is used in this document. For undated references, the latest version (including all amendments) applies to this document.

GB/T601 chemical reagent preparation of standard titration solution.

GB/T625 Chemical reagent Sulfuric acid

GB/T649 Chemical reagent Potassium bromide

GB/T650 Chemical reagent Potassium bromate

GB/T676 Chemical reagent acetic acid (glacial acetic acid)

GB/T684 Chemical Reagent Toluene

GB/T2406.1 Plastics-Determination of Combustion Behavior by Oxygen Index Method-Part 1: Guidance

GB/T6003.1 Wire woven mesh test screen

GB/T6682 Requirements and test methods for analytical laboratory water

3. Product classification specifications

EPS resin according to the characteristics of B, P, F, HF five categories, users have special requirements, according to the contract production, specifications see table 1.

Table 1 Product classification and specifications

|

Brand |

Specifications |

Particle size, mm |

One-time hair rate |

Main use |

|

P common material |

P-103 |

1.00~1.60 |

70~90 |

Plate and low density products |

|

P-104 |

0.85~1.25 |

65~85 |

Wall thickness greater than 12mm products |

|

|

P-105 |

0.70~1.00 |

60~75 |

Medium density packaging |

|

|

P-106 |

0.50~0.80 |

55~70 |

Packaging products with wall thickness greater than 8mm |

|

|

P-107 |

0.40~0.60 |

50~65 |

Packaging products with wall thickness greater than 6mm |

|

|

P-108 |

0.30~0.50 |

35~50 |

Lost Mode Helmet Class Special Solitaire |

|

|

F blocking fuel |

F-103 |

1.00~1.60 |

45~65 |

Plates and large packaging products |

|

F-104 |

0.85~1.25 |

40~65 |

Plates and large packaging products |

|

|

F-105 |

0.70~1.00 |

40~60 |

Plate and medium density packaging products |

|

|

F-106 |

0.50~0.80 |

30~50 |

Heavy plate and special purpose product parts |

|

|

B Quick material |

B-103 |

1.00~1.60 |

60~70 |

Electrical packaging, plate, ceramic packaging low rate products |

|

B-104 |

0.85~1.25 |

50~60 |

||

|

B-105 |

0.70~1.00 |

40~60 |

||

|

B-106 |

0.50~0.80 |

30~50 |

||

|

HF graphite |

HF-103 |

1.00~1.60 |

45~65 |

Plates and large packaging products |

|

HF-104 |

0.85~1.25 |

40~65 |

Plates and large packaging products |

|

|

HF-105 |

0.70~1.00 |

40~60 |

Plate and medium density packaging products |

|

|

HF-106 |

0.50~0.80 |

30~50 |

Heavy plate and special purpose product parts |

|

|

Note: If there are special requirements for particle size, it can be decided by both parties through negotiation. |

||||

4. Requirements

The requirements of EPS resin shall meet the requirements of Table 2.

Table 2 EPS Resin Requirements

|

Project |

Indicators |

|||

|

P |

F |

B |

HF |

|

|

Appearance |

semitransparent spherical particles |

milky white spherical particles |

semitransparent spherical particles |

black spherical particles |

|

Foaming agent (pentane)% |

4~6.8 |

5~8 |

5~8 |

5~8 |

|

Water content% |

≤ 0.8 |

≤ 1.8 |

≤ 0.8 |

≤ 1.8 |

|

Free monomer (styrene)% |

≤ 0.6 |

≤ 0.1 |

≤ 0.3 |

≤ 0.1 |

|

molecular weight |

48000~54000 |

48000~53000 |

40000~51000 |

48000~53000 |

|

Sieve efficiency% |

≥95 |

≥95 |

≥95 |

≥95 |

|

limiting oxygen index |

|

|

|

|

5. Test method

5.1Determination of foaming agent (pentane) content

5.1.1Instruments and equipment

5.1.1.1Chromatograph: with FID detector (temperature programmed):

5.1.1.2Chromatographic data processor (integrator);

5.1.1.3Micro syringe: 10μL

5.1.2Reagents and Materials

5.1.2.1Carrier gas: N2 purity not less than 99.9%(v/v):

Fuel gas: H2 purity not less than 99.9%(v/v):

Combustion booster: purified air.

5.1.2.2Column: SE-30 φ0.32 × 30m glass capillary column;

5.1.2.3Internal standard: n-heptane (analytically pure).

5.1.3chromatographic operating conditions

The column temperature is programmed to increase. In fact, the column temperature is kept at 40 ℃ for 5min, the heating rate is 40 ℃/min, and the final column temperature is 120 ℃;

Injector temperature: 200 ℃;

Detector temperature FID:300 ℃;

Carrier gas (N2) flow: 2 ml/min;

Air flow: 400 ml/min;

Hydrogen flow: 30 ml/min;

Injection volume: 1μL;

Split exhaust: 20 ml/min;

Tail air blowing: 20 ml/min:

5.1.4Sample determination

5.1.4.1Configuration of Internal Standard Solution

Add about 950ml of toluene (GB/T684) into a 1000ml volumetric flask, add 5g (accurate to 0.0002g) and n-heptane (internal standard), dilute to the scale with the same toluene, shake well for later use.

5.1.4.2Determination steps

Weigh 1g sample (accurate to 0.0002g), place it in a 100ml iodine flask, then accurately measure 10ml internal standard solution, and fully shake and dissolve.

Start the preparation of the instrument. After all operating conditions are stable, take 1μL sample and inject it into the gas chromatography vaporization chamber according to the same chromatographic conditions as above. At the same time, start the chromatographic data processor. After the peak of each component is completed, the chromatographic processor will print out the following figure and the peak area of each component and internal standard, and calculate the foaming agent content according to the peak area of each component and internal standard.

5.1.4.3Calculation

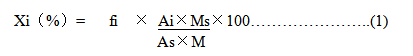

The mass percentage content Xi of the tested component is calculated according to formula (1):

In the formula:

XI-percentage of I component in the sample;

Ai-peak area of component I;

A- ---- peak area of internal standard S;

Fi ---- mass correction factor of component I relative to internal standard

Ms --- total mass of internal standard substance in 1000ml internal standard solution, g;

Mass of M----EPS resin sample, g.

5.1.4.4Results Report

The sum of the mass of n-pentane and isopentane is the blowing agent content. The arithmetic mean of the two parallel measurements is taken as the measurement result, and the relative error of the two parallel measurements is not more than 0.05%.

5.2Determination of styrene monomer content

5.2.1Method Summary

Bromine standard solution (potassium bromide, potassium bromate) generates Br2 under acidic conditions, which in turn can react quantitatively with the free monomer (styrene) in EPS.

5.2.2Reagents and Solutions

The reagents used in this standard are all analytically pure, and the water shall meet the requirements of Class III water in the GB6682-92.

5.2.1Bromine standard solution: C(1/6 KBrO3)= 0.1mol/L, prepared according to GB/T601.

Sodium thiosulfate standard solution: C(Na2S2O3)= 0.1mol/L, prepared according to GB/T601.

5.2.2Acetic acid-sulfuric acid solution, take glacial acetic acid (GB/T676-90)3550ml, sulfuric acid

GB/T625-89)150ml is added with distilled water to prepare 5000ml

5.2.3Toluene (GB/T684-86)

5.3Test steps

5.3.15g of EPS sample (regulated to 0.0002g)(1g of low temperature sample) is added into a 250ml triangular flask and shaken until dissolved. To this solution was added 50ml of acetic acid-sulfuric acid solution. Titrate with bromine standard solution C(1/6 KBrO3)= 0.1mol. Vigorous shaking is required during titration. Titration to Milky White to yellowish color (does not disappear within 15 seconds) is the end point.

5.3.2The blank test was conducted under the same conditions.

5.3.3calculation method

F.M% =0.104 *(V-V0)*C0*100…………(2)

M

Where: F.M%-percentage content of free monomer (styrene) in EPS

C0 ---------- molar concentration of bromine standard solution, mol/L

V,V0 ------- volume of standard solution consumed by sample and blank, ml

0.104 ------- with 1.00ml bromine standard solution (C(1/6 Kbro3))

= 0.0001mol/L) equivalent to the mass of styrene in grams

M ----------- the mass of the sample, g

5.3.4Results Report

The average of two parallel measurements is the free monomer content in the EPS resin. The absolute error of parallel value shall not exceed 0.02%

5.4moisture determination

5.4.1Instrument

1. Electronic balance

2.300mm dryer

3.50ml plastic cup

5.4.2Determination steps

Weigh about 5g of sample into a plastic cup (accurate to 0.1mg), put it into a desiccator filled with color-changing silica gel, and take it out for weighing after 20 ~ 24hr.

5.4.3calculation formula

H2O%=Weighting in total weight-total weight after drying*100%………(3)

Sample weighing

5.5determination of molecular weight

5.5.1Instrument

1 electronic analytical balance (accuracy 0.0001);

2 Erlenmeyer flasks with stoppers (100ml)

3Haake falling ball viscometer

4 electronic stopwatch (accuracy 0.01s)

5 pipettes (50ml)

5.5.2Reagent: toluene (GB/T684)

5.5.3Test steps

5.5.3.1Sample processing

Weigh 7.5g sample and place it in a 250ml beaker, place it in an oven at 120 ℃ and foam until the foam shrinks to slightly separate from the cup wall and bottom. It was removed from the oven and cooled at room temperature. After cooling, the shrunk sample bonded together is transferred to a special copper mortar and loosened.

The purpose of the original particles in the oven is to make the small molecule foaming agent escape, so as not to affect the molecular weight measurement value. In the drying process, should avoid the use of too high temperature and too long time. In order to avoid the molecular chain break and make the molecular weight is low.

5.5.3.2Sample preparation

According to the provisions of Table 3, weigh a certain amount (accurate to 0.001g) of sample and place it in a 100ml conical flask with plug. Pipette into 50ml of toluene and place it in an oscillator to oscillate until it is completely dissolved. The concentration of this solution is 10%.

Table 3 Temperature-Sample Quantity Correcting Table

|

Room temperature (℃) |

Average Specific Gravity of Toluene |

Toluene addition volume, ml |

EPS shrinkage particle weighing quantity, g |

|

0~5 |

0.881 |

50 |

4.89 |

|

5~10 |

0.877 |

50 |

4.87 |

|

10~15 |

0.873 |

50 |

4.85 |

|

15~20 |

0.869 |

50 |

4.83 |

|

20~25 |

0.864 |

50 |

4.80 |

|

25~30 |

0.860 |

50 |

4.78 |

|

30~35 |

0.856 |

50 |

4.76 |

|

35~40 |

0.852 |

50 |

4.73 |

5.5.3.3Measurement steps

Open the water thermostat and adjust the temperature to (25±0.3)℃. Put the dissolved sample into a constant temperature water bath for about 10min

Pour the sample solution after constant temperature into the measuring range of the viscometer, put the steel ball into the hollow plug, close the cover, and then screw the screw cap. The amount of sample added should be that the sample solution can overflow from the capillary of the hollow plug after inserting the hollow plug. Adjust the viscosity over the horizontal spiral foot, so that the air bubble on the viscometer frame contains the whole small circle of the cover.

After the steel ball falls to the bottom of the measuring tube, turn the measuring tube over 180 ° and nail the spring lock on the base frame into the small groove of the viscometer tube holder. When the steel ball falls tangent to the marking ring on the measuring tube, start the stopwatch. Stop timing when the ball falls tangent to the subscript loop. Note the number of seconds of time shown on the table. Turn over the measuring tube and repeat the test until two consecutive readings do not exceed 0.1 seconds, take the average of the two numbers as the measured time, and multiply the measured seconds by the coefficient 0.615 to obtain the viscosity value (CP).

Check the viscosity molecular weight comparison table to obtain the molecular weight value of the measured sample. See Table 4 for the viscosity-molecular weight comparison table.

Table 4 EPS viscosity-molecular weight comparison table (using haake falling ball viscometer)

| Viscosity | molecular weight | Viscosity | molecular weight | Viscosity | molecular weight | Viscosity | molecular weight | Viscosity | molecular weight |

| 6.0 | 32500 | 8.0 | 36100 | 10.0 | 39700 | 12.0 | 43000 | 14.0 | 45900 |

| 6.1 | 32680 | 8.1 | 36280 | 10.1 | 39880 | 12.1 | 43160 | 14.1 | 46040 |

| 6.2 | 32860 | 8.2 | 36460 | 10.2 | 40060 | 12.2 | 43320 | 14.2 | 46180 |

| 6.3 | 33040 | 8.3 | 36640 | 10.3 | 40240 | 12.3 | 43480 | 14.3 | 46320 |

| 6.4 | 33220 | 8.4 | 36820 | 10.4 | 40420 | 12.4 | 43640 | 14.4 | 46460 |

| 6.5 | 33400 | 8.5 | 37000 | 10.5 | 40600 | 12.5 | 43800 | 14.5 | 46600 |

| 6.6 | 33580 | 8.6 | 37180 | 10.6 | 40780 | 12.6 | 43940 | 14.6 | 46740 |

| 6.7 | 33760 | 8.7 | 37360 | 10.7 | 40960 | 12.7 | 44080 | 14.7 | 46880 |

| 6.8 | 33940 | 8.8 | 37540 | 10.8 | 41140 | 12.8 | 44220 | 14.8 | 47020 |

| 6.9 | 34120 | 8.9 | 37720 | 10.9 | 41320 | 12.9 | 44360 | 14.9 | 47160 |

| 7.0 | 34300 | 9.0 | 37900 | 11.0 | 41500 | 13.0 | 44500 | 15.0 | 47300 |

| 7.1 | 34480 | 9.1 | 38080 | 11.1 | 41660 | 13.1 | 44640 | 15.1 | 47420 |

| 7.2 | 34660 | 9.2 | 38260 | 11.2 | 41820 | 13.2 | 44780 | 15.2 | 47540 |

| 7.3 | 34840 | 9.3 | 38440 | 11.3 | 41980 | 13.3 | 44920 | 15.3 | 47660 |

| 7.4 | 35020 | 9.4 | 38620 | 11.4 | 42140 | 13.4 | 45060 | 15.4 | 47780 |

| 7.5 | 35200 | 9.5 | 38800 | 11.5 | 42300 | 13.5 | 45200 | 15.5 | 47900 |

| 7.6 | 35380 | 9.6 | 38980 | 11.6 | 42440 | 13.6 | 45340 | 15.6 | 48000 |

| 7.7 | 35560 | 9.7 | 39160 | 11.7 | 42580 | 13.7 | 45480 | 15.7 | 48100 |

| 7.8 | 35740 | 9.8 | 39340 | 11.8 | 42720 | 13.8 | 45620 | 15.8 | 48200 |

| 7.9 | 35920 | 9.9 | 39520 | 11.9 | 42860 | 13.9 | 45760 | 15.9 | 48300 |

| 16.0 | 48400 | 18.0 | 51000 | 20.0 | 53700 | 22.0 | 56100 | 24.0 | 58500 |

| 16.1 | 48520 | 18.1 | 51140 | 20.1 | 53820 | 22.1 | 56220 | 24.1 | 58610 |

| 16.2 | 48640 | 18.2 | 51280 | 20.2 | 53940 | 22.2 | 56340 | 24.2 | 58720 |

| 16.3 | 48760 | 18.3 | 51420 | 20.3 | 54060 | 22.3 | 56460 | 24.3 | 58830 |

| 16.4 | 48880 | 18.4 | 51560 | 20.4 | 54180 | 22.4 | 56580 | 24.4 | 58940 |

| 16.5 | 49000 | 18.5 | 51700 | 20.5 | 54300 | 22.5 | 56700 | 24.5 | 59050 |

| 16.6 | 49140 | 18.6 | 51860 | 20.6 | 54420 | 22.6 | 56820 | 24.6 | 59160 |

| 16.7 | 49280 | 18.7 | 52020 | 20.7 | 54540 | 22.7 | 56940 | 24.7 | 59270 |

| 16.8 | 49420 | 18.8 | 52180 | 20.8 | 54660 | 22.8 | 57060 | 24.8 | 59380 |

| 16.9 | 49560 | 18.9 | 52340 | 20.9 | 54780 | 22.9 | 57180 | 24.9 | 59490 |

| 17.0 | 49700 | 19.0 | 52500 | 21.0 | 54900 | 23.0 | 57300 | 25.0 | 59600 |

| 17.1 | 49840 | 19.1 | 52640 | 21.1 | 55020 | 23.1 | 57420 | 25.1 | 59710 |

| 17.2 | 49980 | 19.2 | 52780 | 21.2 | 55140 | 23.2 | 57540 | 25.2 | 59820 |

| 17.3 | 50120 | 19.3 | 52920 | 21.3 | 55260 | 23.3 | 57660 | 25.3 | 59930 |

| 17.4 | 50260 | 19.4 | 53060 | 21.4 | 55380 | 23.4 | 57780 | 25.4 | 60040 |

| 17.5 | 50400 | 19.5 | 53200 | 21.5 | 55500 | 23.5 | 57900 | 25.5 | 60150 |

| 17.6 | 50520 | 19.6 | 53300 | 21.6 | 55620 | 23.6 | 58020 | 25.6 | 60260 |

| 17.7 | 50640 | 19.7 | 53400 | 21.7 | 55740 | 23.7 | 58140 | 25.7 | 60370 |

5.6determination of particle sieve analysis

5.6.1Summary of methods

After the sample is screened with a standard screen, the mass of the sample on each mesh is weighed and calculated as a percentage. The sieving efficiency of EPS resin is defined as the maximum value of the sum of the percentages of three consecutive screens.

5.6.2Instrument

1. The test sieve shall meet the requirements of the GB6003.1-1997, and the diameter of the sieve frame shall be D = 210mm.

Height H = 50mm, wire woven screen surface, according to the particle size range of the product to be tested to choose a set.

Sieve of specified aperture with corresponding base and cover. EPS resin selected screen specifications

Table 1 below:

|

Screen mesh |

7.5 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

|

Corresponding aperture m/m |

2.50 |

2.38 |

2.00 |

1.68 |

1.43 |

1.25 |

1.00 |

0.84 |

0.71 |

0.63 |

0.50 |

0.42 |

0.36 |

0.30 |

2 One set of standard sample screening

3 electronic balance, inductance 0.1g

4 soft leather brushes

5.6.3Test steps

3.1Select a set of sieves according to the specifications of EPS resin. See Table 4 below for details. The sieves are required to be clean and clean. According to the order of aperture from small to large, overlap from bottom to top as a sieve group, and place the sieve group on the chassis.

3.2Weigh 100±1g of the shaken sample (weigh it to 0.1g), place it in the upper sieve, and add a sieve cover.

3.3Shake the sample sieve group by hand for 1min ± 30s, take down the chassis and the sieve group after stopping the oscillation, collect and weigh the sample mass in each sieve and the chassis respectively (carefully brush the particles attached to the sieve surface with a brush)

|

EPS resin specification |

103 |

104 |

105 |

106 |

|

Selected sieve (mesh) |

10~ 18 |

14~ 25 |

16~ 30 |

20~ 40 |

3.4Calculation of sieve analysis efficiency results

According to the mass of the sample remaining on the sieve tray, calculate the percentage AI(%) of each particle size according to the following formula:

AI(%)= Bi *100…………(3)

M

In the formula: AI% I mass percentage of sieve layer residue to the total sample,%;

Mass of residual sample in BI I sieve layer, g

M -- Mass of sample g

The sieving efficiency of EPS resin is the value when the sum of AI of three consecutive screens is the maximum value,

That is, sieve analysis efficiency (%)= max(AI + AI +1 + AI +2)

3.5Calculation of average particle size results

X=H (aperture corresponding to mesh number) * AI (see 3.4) h1 * Ai1

100

5.7Determination of limiting oxygen index

EPS resin pre-foaming, after molding. According to GB/T2406.1.

6. Inspection rules

6.1Group Batch

EPS resin to every 8h production of the same specifications of the product for a batch

6.2Sampling

Sampling shall be carried out on the packaging line in accordance with GB/T 6679.

6.3inspection and judgment

Delivery inspection of EPS resin

Inspection items: foaming agent content, residual styrene, water content, and sieve analysis efficiency

The delivery inspection shall be carried out by the quality inspection department in accordance with the inspection methods specified in this standard. And issued a quality certificate. If it does not meet the requirements of this standard, it shall be re-sampled and re-inspected. If the results are still unqualified, the batch of products shall be downgraded or treated as unqualified.

7,Packaging, Marking, Storage and Transportation

7.1EPS resin packaging can be used PP woven outer bag or composite PP bag or other packaging, each package must have PE or composite PE inner bag. The mouth of the bag shall be tied or sewn to reduce the loss of foaming agent.

7.2The product must be accompanied by a quality certificate issued by the product inspection department.

7.3 The manufacturer's name, address, product name, brand, batch number, material type, specification, net weight, production date, product quality, number of this standard, and signs such as "fear of wetness", "no smoking" and "no fire" shall be marked on the packaging apparatus.

7.4EPS resin shall be stored in sealed containers. After packaging, EPS resin should be placed in a cool and well-ventilated place as much as possible. In order to prevent the loss of foaming agent, it should be kept below 25 ℃ and ventilated. Fire sources (including fireworks, static electricity, flash, etc.) are absolutely prohibited to avoid danger.

7.5 EPS resin should be transported in clean and covered carriages. It is forbidden to mix with other dangerous goods or organic solvent instruments and eliminate fire danger.